Products News

Bonding – between flexibility and rigidity for PCB reliability.

Bonding – between flexibility and rigidity for PCB reliability

ABchimie offers a wide range of adhesives to maintain electronic components to make the electronics devices more reliable and to protect them against corrosion. Depending on the environment where the electronic PCB are integrated (humidity, vibrations, salt spray, high temperature, etc.), several solutions are possible:

- RTV silicone

- 2 components epoxy resin

- 2 components polyurethane resin

- UV curing glue

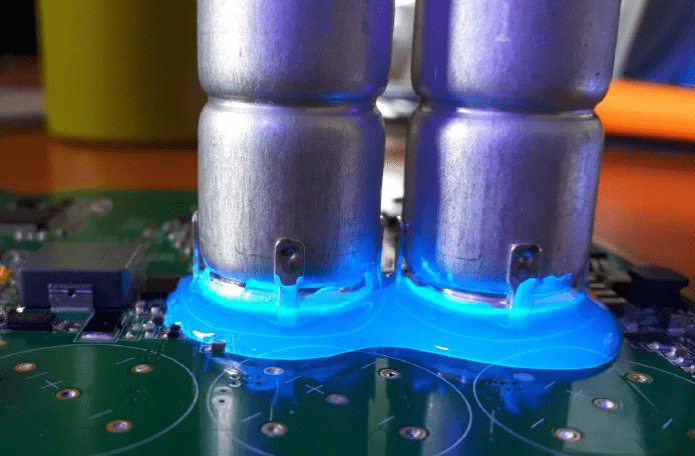

RTV silicones cure with the moisture of the air and provide excellent mechanical protection due to their flexibility.

Often used to maintain electronic capacitors, RTV silicone adhesives absorb potential shocks and vibrations.

When no movement of the components is tolerated, two-component epoxy or polyurethane solutions are often used. These glues are generally more rigid and prevent any movement of the components. A glob top can even sometimes be used to completely protect some sensitive components or even the entire electronic system against all external aggressions (chemical aggression, water penetration, abrasions, hacking, etc.). These solutions can be applied manually using two-component cartridges and a static mixer to mix the resin with its hardener, or more industrially using a in line machines.

Nevertheless, more and more gluing are made with UV curable glues. These solutions allow bonding up to 5mm thick with a drying time of a few seconds under UV lamps. These UV glues have the advantage of being available in different ways: fluid to very viscous, flexible to very rigid, with or without tracer… ABchimie has real expertise and can modify formulations of the glues in order to perfectly meet their customer specifications.

The main advantage of UV glues is that they reduce the size of production lines and reduce production time due to their very quick drying time. The application of the glue can be done at the same time as the deposit of the conformal coating, and this with a single passage in the UV oven.

Concrete case: ABchimie has developed the ABchimie 6025 UV glue which is a very high viscosity and flexible mercury or LED curing glue (similar to a standard RTV silicone). This product allows to handle the PCB directly after curing and has real advantages for customers with a high production volume. It is even possible to:

- Glue components in one side of the PCB

- Cure it with a UV lamp

- Flip the PCB

- Put the PCB on the other side

- Put the PCB in a reflow oven to solder the top & bottom side at the same time.